Where business meets technology!

Simple administrative positions are already computerized and assembly line work is being done by robots. Technology is getting more complex and the development cycle is getting faster every day. If your company want to compete and stay on the top of your business, the only way is to invest in information technology to drive technology and process innovation, standardization and optimization.

Every optimalization or standardization project starts with defining the process

Defining the process is the crucial first step in any optimization or standardization project. It’s like setting the foundation before you start building. You need a clear understanding of the current state of the process to know where the inefficiencies lie or where improvements can be made.

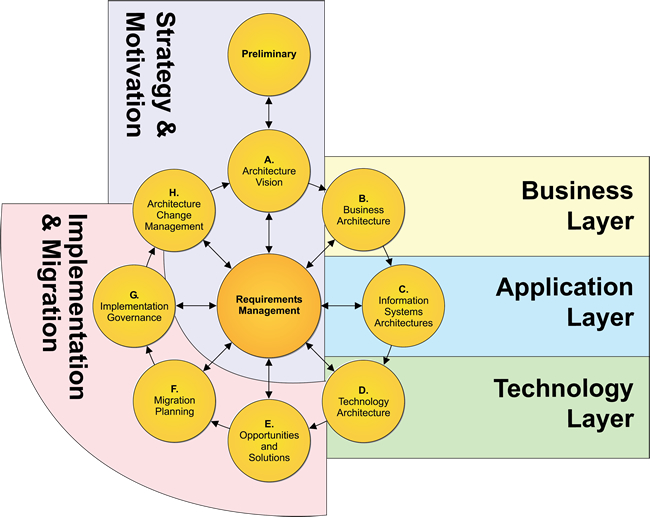

Combining Business Architecture from TOGAF with ISA-88 (Batch Control Standards) creates a comprehensive approach to standardizing and aligning business and technological strategies, especially within manufacturing or process industries. This combination ensures that your business processes, capabilities, and value streams are optimized with standardized control systems that improve operational efficiency, reduce risk, and enable scalability.

Why optimalization though standardization

Standardization leads to increased efficiency, reduced downtime, improved quality, and easier scaling of the system. Additionally, it ensures that you can easily adapt to new products and integrate new equipment without major rework.

Mechatronic standardization refers to the process of creating and implementing uniform standards for the design, manufacturing, and integration of mechatronic systems. Mechatronics, which combines mechanical, electrical, and software engineering, involves complex systems where these different domains need to work seamlessly together. Standardization ensures that the components, interfaces, and communication protocols are consistent across different systems, making them more reliable, interchangeable, and scalable.

The goal of mechatronic standardization is to:

- Improve Interoperability: By setting common standards, mechatronic components (e.g., sensors, actuators, controllers) from different manufacturers can work together seamlessly.

- Enhance Efficiency: Standardized components reduce development time, as engineers don’t have to reinvent the wheel for each new system.

- Reduce Costs: By using common parts and designs, companies can benefit from economies of scale, reducing both production and maintenance costs.

- Increase Reliability and Quality: Standards often incorporate best practices that lead to more reliable and durable products.

- Simplify Maintenance and Upgrades: Standardization makes it easier to maintain and upgrade systems because parts are interchangeable, and the system architecture is consistent.

Combining version control with standardization in mechatronics helps teams collaborate more effectively, ensures system compatibility, and maintains high quality throughout the development and lifecycle of the system. MMCE can help you with mechatronic or/and process standardization.